Handmade Glazed tile manufacturing process

BongTiles handcrafted handmade glazed tiles are formed from highly skilled workers who are dedicated to the profession and always follow a strict production process to ensure the highest quality of handmade glazed tiles. with market trends. Each tile is unique and unique. Please Contact BongTiles for the best price of tiles.

8 Steps for producing handmade glazed tiles follow BongTiles's process

Step 1: Selection and mixing the soil

Choose a good source of clay materials, ensure the purest material source, filtering out all impurities. The filtered soil will be mixed with many different compounds, this is important step to help forming handmade glazed ceramic tiles with high hardness and durability.

Step 2: Shaping handmade glazed ceramic tiles

Handmade glazed ceramic tiles are shaped by the forms. Different forms would bring different shapes and sizes.

Step 3: The handmade glazed ceramic tiles curing and drying process

After being shaped, the clay tiles will be cured and dried in room temperature before the enamel spraying process. In this stage, the clay tile will be evaporated and shrinked about 5-10% compared wet clay tile. This explains why handmade glazed ceramic tiles have an irregular size, so in the tiling process, the worker shall use at least 2-3 mm grouting to ensure easy work and aesthetic looking.

Step 4: Enamel mixing process

Handmade glazed ceramic tiles are beautiful, durable and valuable thanks to the ceramic glaze. This glaze is the secret of each manufacturer, inherited and developed through many different generations.The raw enamel materials of BongTiles's handmade ceramic glaze are selected and filtered cleanly, with color developed from oxides pigment available in the nature to ensure the hardness, durability and shining. Unlike industrial made ceramic tile, BongTiles handmade glaze are mixed manually, the color of each handmade ceramic tiles has a variation, making a unique looking after clading.

Step 5: Handmade glazed ceramic enamel coating process

Ceramic glaze is a layer of glass covering the surface of the clay tile to help protect and create the aesthetics and value of handmade glazed ceramic tiles. This enamel layer has a thickness of about 0.2 to 0.5 mm.

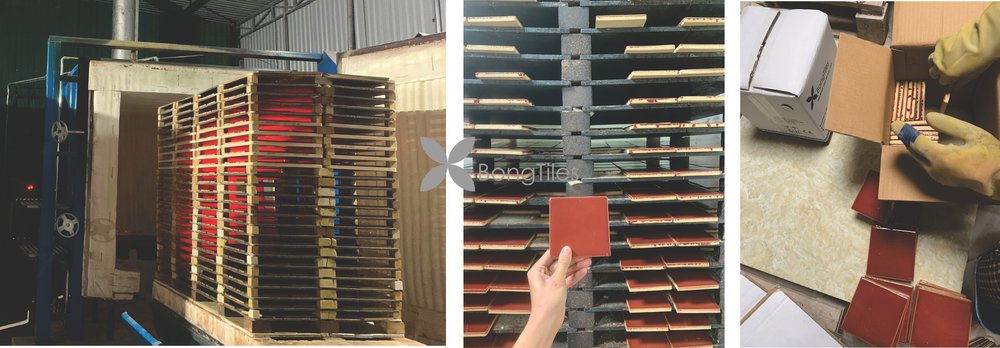

Step 6: Put tiles in to kiln

Clay tiles after being enameled will be arranged on the gong, the arrangement of clay tile on the gong must ensure the most optimization of the surface area of the blister, in addition to ensure ventilation for heat convection when heated.

Step 7: Handmade glazed ceramic tiles firing

Clay tiles are fired by gas kiln within 15-18 hours until the clay is completely ripe and the enamel layer on the tiles forms a glossy or translucent enamel surface. The temperature in the kiln in the final stage was over 1200 degrees Celsius.

Step 8: Inspection and packing

After being fired, the handmade glazed ceramic tiles must be cooled naturally. After the oven temperature returns to a safe level, the handmade glazed ceramic tiles will be pulled out of the kiln, then the handmade glazed ceramic tiles will be taken down for QC’s inspection and packing.

Encaustic Viet Nam Cement Tiles

Encaustic Viet Nam Cement Tiles

Traditional handmade glazed terracotta tiles

Traditional handmade glazed terracotta tiles

Authentic concrete terrazzo tiles/customized products

Authentic concrete terrazzo tiles/customized products

Hexagon Cement Tiles

Hexagon Cement Tiles

Encaustic Cement Tiles

Encaustic Cement Tiles

Terrazzo Cement Tiles

Terrazzo Cement Tiles

Brass Insert Cement Tiles

Brass Insert Cement Tiles

Border and corner

Border and corner

Traditional handmade glazed terracotta tiles

Traditional handmade glazed terracotta tiles

Concrete terrazzo Basin

Concrete terrazzo Basin

Large sized concrete authentic terrazzo Tiles

Large sized concrete authentic terrazzo Tiles

Terrazzo floors

Terrazzo floors

Concrete Terrazzo Bathtub

Concrete Terrazzo Bathtub

Encaustic Handmade Cement Tile BV124-3

Encaustic Handmade Cement Tile BV124-3

Encaustic Handmade Cement Tile BV124-2

Encaustic Handmade Cement Tile BV124-2

Encaustic Handmade Cement Tile BV113

Encaustic Handmade Cement Tile BV113

Handmade terrazzo BathTub BT1600.S1.1000.G23.TAX

Handmade terrazzo BathTub BT1600.S1.1000.G23.TAX

Handmade terrazzo BathTub BT1600.S1.7014.QC

Handmade terrazzo BathTub BT1600.S1.7014.QC

Handmade terrazzo BathTub BT1500.S4.1000.G23.BYR5

Handmade terrazzo BathTub BT1500.S4.1000.G23.BYR5